Auto Parts Vacuum Press Machine / Rubber Molding Machine To Make Rubber Bellow

Product Details:

| Place of Origin: | China |

| Brand Name: | Juchuan |

| Certification: | ISO9001:2015 |

| Model Number: | JC-VF |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1set |

|---|---|

| Price: | USD 24000-40000/set |

| Packaging Details: | container |

| Delivery Time: | 60days |

| Payment Terms: | L/C, T/T, Western Union |

| Supply Ability: | 100 Sets per Month |

|

Detail Information |

|||

| Clamp Force(Ton): | 100 - 800 | Plunger Stroke(mm): | 200 - 350 |

|---|---|---|---|

| Mold Opening Type: | 2RT-3RT-4RT-Track | Max. Operating Pressure(MPa): | 2RT-3RT-4RT |

| Motor Power(KW): | 5.5*2-11 | Heating Power(KW): | 7.2*2 - 90 |

| Highlight: | Vacuum Compression Molding Press,Vacuum Compression Molding Equipment,Vacuum Compression Press |

||

Product Description

Auto Parts Vacuum Press Machine / Rubber Molding Machine To Make Rubber Bellow

![]()

Advanced Vacuum Compression Molding Machine Technology:

- Special insertion device: can be customized according to customer requirements. It is mainly used to lock the second and third layers without separation when the three-layer mold is opened.

- There is a separate pressure gauge on the vacuum cover to show the pumping pressure, which is convenient for timely observation of the pumping state.

- Mainly applicable to: rubber silicone fittings with complex structure and difficult exhaust.

Vacuum plate vulcanizing machine Features:

- using dual motor double pump double oil circuit System design, two working positions are independently controlled and operated independently.

- the front top opening and closing moldIn the way, the mold is pushed out from the clamping mechanism, and the mold is opened in front of the machine to facilitate the taking of the product;

- the use of high vacuum vacuum cover design, the mold can be in a near-complete vacuum environment, improve mold exhaust performance;

- The vacuum cover is completed above the vacuum of -650mmHG within 4 seconds. It is not suitable for forming, and the precision finished product is most suitable;

- Reduce the vulcanizing time, improve the products qualified rate, improve the working efficiency of the machine.

Vacuum plate vulcanizing machine application:

- O-ring, pressing, keyboard, roller, medical drug plug, shockproof products, black rubber products, daily necessities, gaskets, conductive products, electronic products, etc.

- Do not apply to the production of long and large insulator products or other products. When the rubber injection machine is opened, the opening is upward, which is suitable for lifting and removing the product by driving.

Main Technical Parameters:

| Model | Unit | 300VF |

| Clamping Force | Ton | 300 |

| Upper Platen Size | mm | 680*680 |

| Lower Platen Size | mm | 700*800 |

| Plunger stroke | mm | 300 |

| Distance of Thermo-plate | mm | 300 |

| Distance of Tie bar | mm | 785*380 |

| Die sinking type | 2RT-3RT-4RT-Track | |

| Max Operating Pressure | Mpa | 20 |

| Motor Power | hp | 10*2(7.5KW*2) |

| Electric Heating Power | Kw | 24*2 |

| Vacuum Pump Power | Kw | 3*2 |

| Total Power | Kw | 69 |

| Gross weight | Ton | 15.45 |

| Dimension | mm | L3360*W2970*H2850 |

Other Vacuum Compression Machine Parameters:

| Model | Unit | 200VF | 250VF | 300VF | 400VF | 500VF |

| Clamping Force | Ton | 200 | 250 | 300 | 400 | 500 |

| Upper Platen Size | mm | 510*510 | 600*600 | 680*680 | 800*800 | 950*950 |

| Lower Platen Size | mm | 550*560 | 650*600 | 700*800 | 850*850 | 1000*1000 |

| Plunger stroke | mm | 250 | 250 | 300 | 350 | 350 |

|

Distance of Thermo - plate |

mm | 250 | 250 | 300 | 350 | 350 |

| Distance of Tie bar | mm | 640*310 | 745*310 | 785*380 | 940*450 | 1105*475 |

| Die sinking type | 2RT-3RT-4RT-Track | |||||

|

Max Operating Pressure |

Mpa | 20 | 20 | 20 | 20 | 20 |

| Motor Power | hp | 10*2 | 10*2 | 10*2 | 15*2 | 15 |

|

Electric Heating Power |

Kw | 13.5*2 | 15.3*2 | 24*2 | 26.4*2 | 36 |

|

Vacuum Pump Power |

Kw | 3 | 3*2 | 3*2 | 3*2 | 4 |

| Total Power | Kw | 45 | 51.6 | 69 | 84.8 | 49 |

| Gross weight | Ton | 7.8 | 11 | 15.45 | 18 | 14.5 |

| Dimension | mm | 2930*2500*2350 | 3190*2930*2495 | 3360*2970*2850 | 3650*3050*2900 | 1460*3600*3150 |

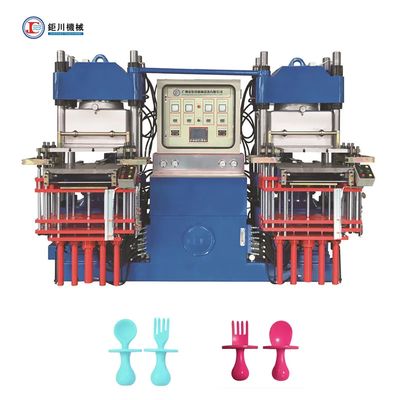

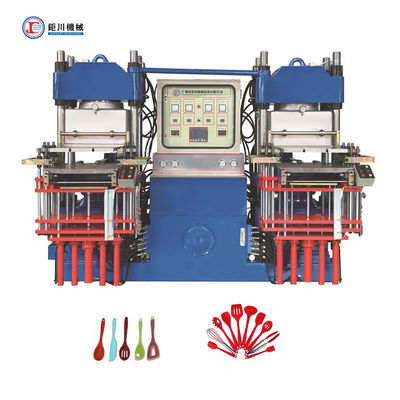

what product our machine can make?

![]()

![]()

![]()

![]()

Exhibition

![]()

1. Free technology training: you can come for inspection and training for free.

2. Free Installation and debugging: Our engineers will teach you about the installation and debugging for free.

3. After-sales service: We will supply the free repairmen on this machine for one year, but will supply the maintenance lifetime. (The service is only for natural damage)

4. Online remote control for software problems, whatspp or wechat for video checking.